On November 6, the LightHouse held its first-ever soldering workshop for people who are blind or have low vision. It was a huge success, and we have the photographs to prove it! Scroll down for more.

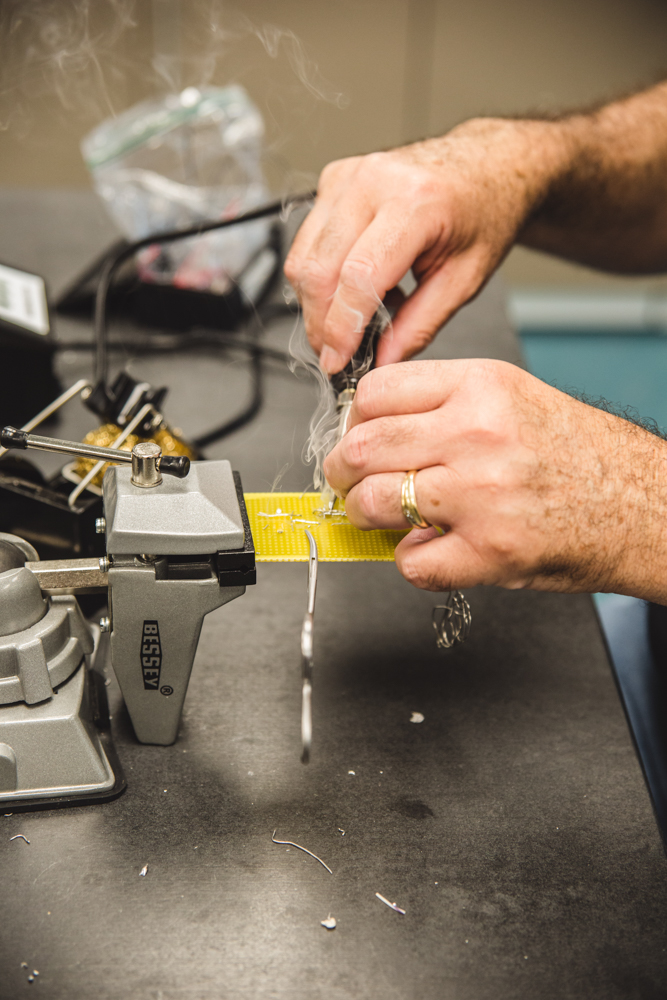

Soldering is a fundamental skill in electronics work that involves using a hot iron to fuse metal to form a permanent connection between electronic components. The aim of the workshop was to help students make their own accessible continuity testers – one of the most fundamental tools for students working in electronics without vision.

While most continuity testers use lights to indicate the strength of electric currents, accessible continuity testers emit a range of tones — high for a free path and low for an impeded path. Unfortunately, accessible continuity testers cannot be purchased, and previous manufacturers have ceased production. Each student left the workshop with a fully-functioning accessible continuity tester for use in their future work; and the skills to solder it themselves.

LightHouse extends a special thanks to Dr. Joshua Miele, Associate Director of the Smith-Kettlewell Eye Research Institute, for facilitating the workshop.

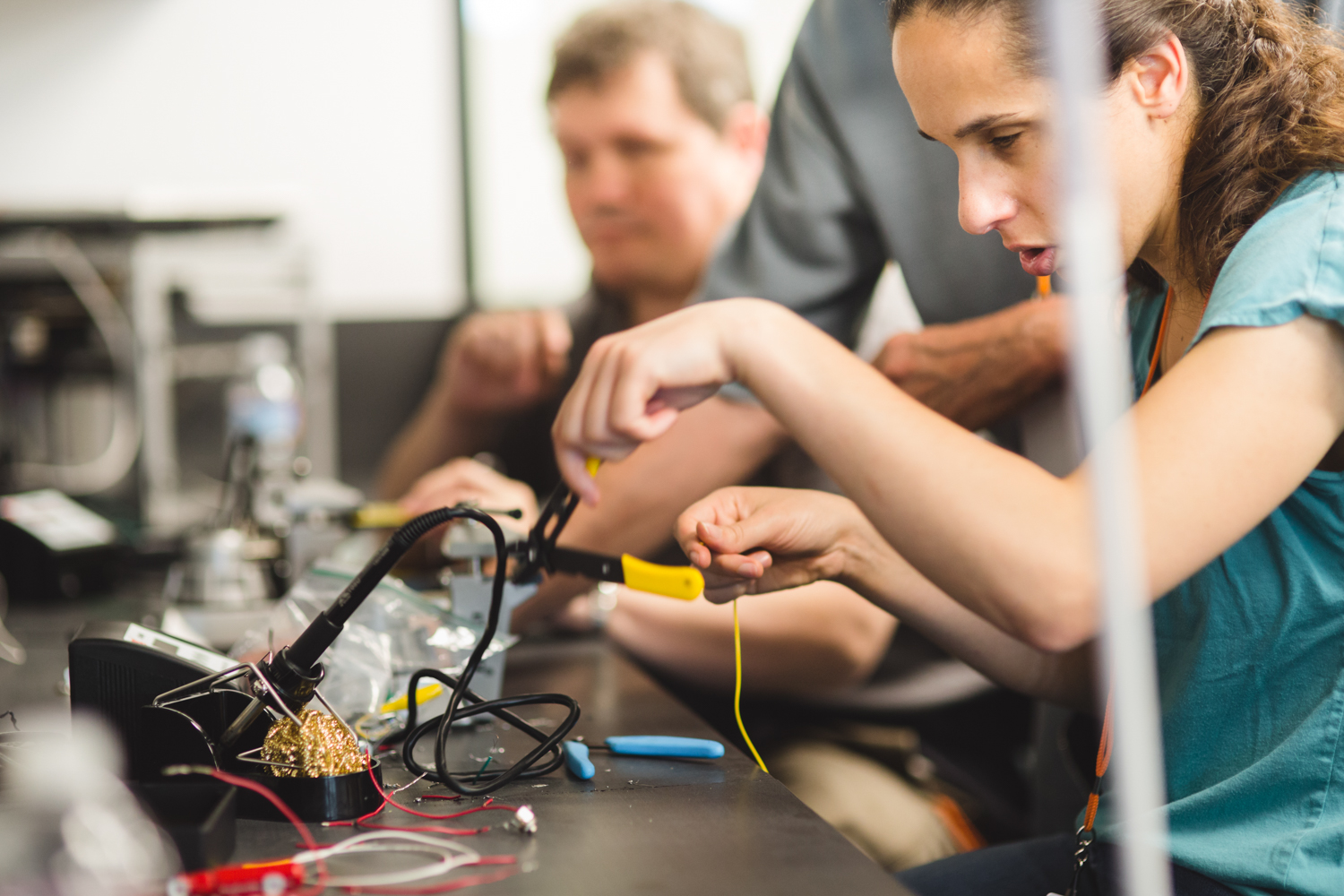

“Blind people are makers. We can do things like soldering and building robots and woodworking,” says Dr. Miele. “We might use slightly different techniques, but the outcome is the same. The LightHouse is all about teaching these alternative techniques so that people can engage in the activities they love, whether they’re sighted or not.”

Here are a few lovely shots from the workshop, by photographer Erin Conger:

The LightHouse’s Innovation Lab will continue to offer workshops in STEM fields, so stay tuned. It is part of our mission to strengthen the representation of people who are blind or have low vision in the tech industry and other STEM fields.

For more information about future workshops visit the LightHouse Calendar or contact Director of Community Services Lisamaria Martinez via email at info@lighthouse-sf.org or by phone at 415-431-1481.